Plant Automation

HKDesk Team has extensive experience with the automation of industrial plants in different sectors like oil and gas, agro, electricity, steel and manufacturing etc.

We can guarantee the correct implementation of all phases engineering, supply, assembly and commissioning. This includes powerful process control, stable process optimization systems and solutions for quality-assured production.

As repeatedly demonstrated, our solutions can significantly improve the performance of production and the quality of your product. This leads to plant-wide standardization for maximized plant performance, availability and flexibility.

We design and engineer custom-automated control solutions

In the era of digitalisation, the technological revolution in the field of Industrial automation is also required. There must be actionable communication connectivity between plant machineries and control system. This Technical integration between process control systems and information across the plant, enables standard production, process optimization and quality improvement.

We offer you ascendable, future-proof solutions built on latest technologies to help you to develop a real-time, secured plant infrastructure that will help you deliver the most valuable results.

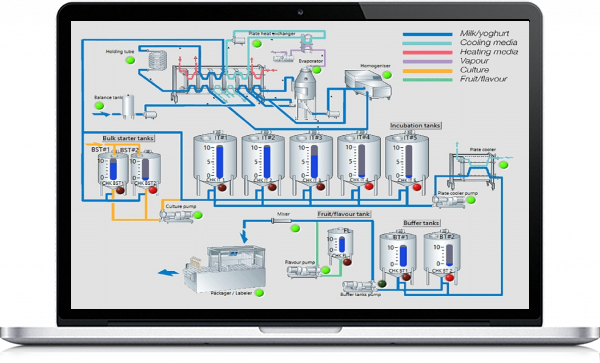

SCADA / HMI

SCADA (Supervisory Control and Data Acquisition) or HMI (Human Machine Interface) systems allow operators, engineers and supervisors of manufacturing facilities to visualize, control, and analyze plant floor data in order to make decisions about improving processes.

HKDesk Automation can connect all of your Ethernet based Allen Bradley, Schneider, Omnon or Modbus controllers with your SQL databases to create a customized visualization client to do all of the following and more:

Internet of Things (IoT)

Our Services

From concept to production, we are committed to developing, building and maintaining quality automation systems that help you reach your goals. Whether your aim is reduced downtime, improved quality, increased efficiency and productivity, enhanced safety or reduced energy costs, HKDesk’re here to help with professional service and expertise you can rely on.

Case Studies

HKDesk has worked closely with a variety of companies in diverse industries to develop new systems and to cost-effectively enhance the capabilities of existing machines. As a result of our work together, customers have enjoyed reduced downtime and waste, improved quality, increased efficiency and productivity, enhanced safety, and reduced energy costs.

Upgrading, Maintenance and Repair of Plant Automation System

Your existing plant controls and automation equipment cannot be ignored and needs to be upgraded when system components are no longer available or software is no longer supported. We can upgrade your existing control and automation equipment, so you no longer have to worry about parts availability, software support, or making updates to your automation programs.

What HKDesk Offer

We offer to monitor and service your control system remotely utilizing remote VPN access capabilities saving you time and money. We will recommend any preventative maintenance procedures and train your personnel to perform maintenance items.

Why Remote Maintenance and Service?

Maintenance and ongoing service, from your system integrators, is essential to a well running system.

We are able to provide remote maintenance to locations throughout India.

Remote maintenance and service for Plant / Machine Automation:

Eliminates travel costs for service.

Eliminates the 'wait' time for service to begin.

We are the backup support to your staff for your system maintenance or repair.

Disaster recovery we save a copy of your programs and updates on our file server providing you off-site backup for recovery in the event when it is required.

Plant Automation Pricing

At HKDesk, our pricing varies based on deployment, hardware, number of I/O and other variables.

We are here to help you figure out the best option for your automation system needs.

If you have any query, please reach to us at

info@hkdesk.com.

Frequently asked questions

Why Automate?

- Reduce Downtime

- Improve Quality

- Increase Productivity

- Enhance Safety

- Reduce Energy Cost

What is SCADA?

Supervisory Control And Data Acquisition (SCADA) is a control system architecture comprising: PLC’s, Ethernet capable control equipment, computers, smart devices, databases, networked data communications and graphical user interfaces (GUI) for high-level process supervisory management to interface with an entire plant, process, or individual machine.

Know more about Custom .Net Based SCADA Application By HKDesk.

When should I consider upgrading my automation equipment?

If you have critical control and automation equipment that has components that are no longer available or the software that is running your equipment has an operating system that is no longer supported, it maybe time to consider an upgrade.

Do you offer bigger plans?

If you anticipate needing a higher transaction volume, contact us and we can create a custom plan for you.

Further questions?

If you have any questions or need to discuss to your individual needs, please contact us !